Success Story: Project Analysis

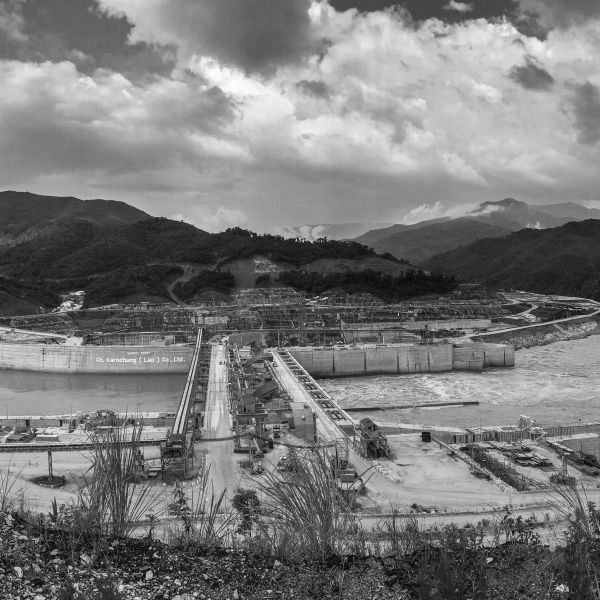

Project Analysis during the Construction of a Large-Scale Power Plant on the Mekong River in Laos

Project analysis is often done when projects are already in trouble or even in crisis. They can shed light on the causes of difficult situations and assess the effects. The later in a project the analysis happens, the lower the possibilities of influence.

The project managers of the Xajaburi project commissioned centerline/ in good time to analyze very specifically the construction site management and to propose concrete optimization potentials before the project reached the critical phase of equipment assembly.

The Analysis

The consulting team worked together with the English cooperation partner Kingsfield from London, which primarily dealt with change and claim management in the analysis. As the leader of this consulting team, centerline/ examined project management, construction site organization, communication, stakeholder management and the most important processes on the construction site (for example, storage management, material receipt, etc.).

These topics also included the very complex communication between the different companies on the construction site as well as in the mother countries (India, China, Thailand, Laos, Austria) of the companies involved. After all, in order to get as true a picture of the situation as possible, it was necessary to take a look at the project teams that were NOT on site.

The Results

The analysis report is based on the results of the site and project team interviews, as well as a variety of project documents that were given to the consultant team. centerline/ and Kingsfield were able to provide the client with very specific recommendations on several key issues, helping to steer the project in a successful direction. These cannot be published in detail due to confidentiality.

However, a few selected points can be stated at least roughly:

- Management capacities were increased for improved site organization.

- Communication structures were adequate at the time of the analysis, but were structured more clearly for the subsequent intensive phase to ensure better information transfer between all parties involved.

- More specific definition of performance progress measurement, specifically for assembly progress (earned value analysis) and optimization of assembly scheduling. This was particularly important with regard to extension-of-time and should enable better traceable time-impact analyses.

It was very gratifying for centerline/ to see that the project was set up well from the client's point of view and that the recommendations in this case were not crisis management measures, but real optimizations to be able to complete the project successfully in terms of schedule and commercial success.

Alexander Kogler, Managing Partner centerline/:

Error Correction Costs Increase Massively over the Course of the Project

"Empirically, the problem often experienced as real - also known as the 'rule of ten' - has been proven and is well known: The later an error or problem is corrected, the higher the costs become - and not in a linear fashion, but almost exponentially. So it was all the more gratifying when we got the chance to take a closer look at a major project in Southeast Asia, even though there was no crisis far and wide and - according to our client - the project was only just beginning to face the bigger challenges."

Services that might interest you based on this success story: